The current Svend Frederiksen Maskinfabrik A/S was founded on June 19, 1961. The company was started in Ryslinge as Ryslinge Maskinværksted by Svend Frederiksen. Svend Frederiksen was born in 1934 to carpenter Hans Peder Frederiksen and Jensine Frederiksen. Jensine[1] was the sister of Kresten Pedersen, who started Boltinge Stolefabrik.

Svend Frederiksen lived in many different places on Funen during his childhood and youth. Among other things, for a period in Tøyjstrup, where his father worked as a carpenter.

Svend was trained as a carriage and fittings smith at Harald Nielsen, who had the forge in Vantinge. He also worked for a number of years at Boysen in Ringe before he started on his own. He has probably always been known to be a bit of a jack-of-all-trades and enjoyed the reputation that if there was something you could not get made or get to work, then you could always try to go to Svend. He married Birthe Frederiksen, who for many years, among other things, took care of the bookkeeping as an assisting spouse.

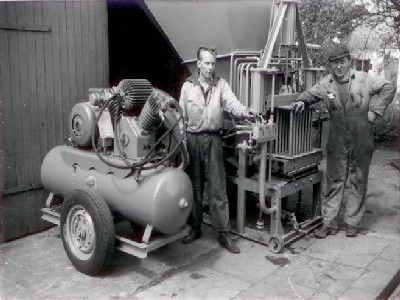

The company was started on the basis of assembly and repair work on cement foundry machines. The tools at that time consisted of a toolbox, a hand drill, an angle grinder, an electric welder, an oxyacetylene welder and a van. And the workshop consisted of a garage of thirty square meters. At that time, the hourly rate was about DKK 10.00 and the customer paid about DKK 1.25 per kilogram of iron. The following year in 1962, the space became too cramped and the garage was expanded by twenty square meters. New acquisitions that year consisted of a cold saw and a pillar drill. In the same year, the company hired its first apprentice, Torben Pedersen, who for many years afterwards was a highly valued and respected leader of the fitters at Faber A/S in Ryslinge. In 1963, two more journeymen and an apprentice were hired. Furthermore, a lathe, a milling machine and another van were acquired. At this time, the company started manufacturing molds and machines for cement product factories. It was also in this year that the son and current owner, Fleming Frederiksen, was born.

In 1964, the space in the garage again becomes too small and the company buys a disused country estate in Sødinge, where a machine factory of about 200 square meters and with associated housing is established. In fact, there was an old smithy on the property, which was demolished when we bought it. On old maps you can see that there has been a smithy for more than 100 years. The farmhouse itself dates from 1888. Two more apprentices and a svend are hired. At this time, the company has started to manufacture machinery for entire mortar plants and assembles these around the country.

The period from 1965 to 1971 passes without major changes in work and number of employees. However, there are a few minor expansions of the workshop during the period. Of more noteworthy tasks are, for example, a sludge sucker for Ringe Municipality and a large motorboat for the company's neighbor, Sven Kyhl from Provinsbanken. It is also during this period that a production of cold water cleaners and hot water cleaners with Japanese Cat pumps (high-pressure cleaners) is started up. The company was called Centerclean. Unfortunately, the company ends up losing a large amount of money when an agent fails to fulfill his obligations and the company has to close again.

From 1972 onwards, the company downsizes its activities. After having been out and about doing repair work and the like, the employees are now increasingly drawn back to the workshop and the company moves on to more subcontracting work. The company is now changing shape to become more of a production company.

It is also at the same time that the company has the pleasure of becoming a subcontractor to first Kompan and later Nassau Door. Both companies remain customers to this day.

Kompan establishes itself down the street on Sødingevej in a disused carpentry and joinery workshop and it is not long before Tom Lindhardt Wils and Svend Frederiksen start playing together on the first steel constructions for Kompan. We made handles for the Spilophønen, see-saws, swings, distance tubes, foundations, sliding bars, swinging buoys, Motorikker and many other exciting constructions. I myself have had the pleasure, as a boy, to go to the accountant at Kompan and get paid large sums of money in cash for the work we had done and which I could then proudly carry home. During my apprenticeship, I also had the pleasure of playing along with Tom when he had just had a new good idea that needed to be tested. I remember him as a fantastically creative and skilled person. And then he had the wonderful attitude that he did not think Kompan could afford to have subcontractors who did not make money.

Those were great times. Kompan was sold to Lego in 1996, which meant that we had the pleasure of manufacturing various equipment and furniture for Legoland Parks in Windsor in England, Carslbad in California and Günzburg in Germany. In 2005, the investment fund Nordic Capital took over the majority shareholding in Kompan, which can celebrate its 40th anniversary in 2010.

It was also in 1970 that schoolteacher Peter Damgaard founded Nassau Door A/S and moved the company to newly acquired premises in Ringe in 1971. It is said to be a chance meeting with a Norwegian with knowledge of a new type of lift gate that brings Damgaard into an area he has no prior knowledge of. "Over the years, we have produced many different types of special machines, fittings and components for these gates. You have to say that Peter Damgaard had a format, whether you liked him or not. We have sometimes joked that we were probably the only supplier to Nassau who had been able to supply them for so many years without having had a lawsuit with them. Personally, both my father and I have always felt that we had an excellent relationship with Peter. I think it was a matter of mutual respect. Nassau was sold to Nielsen & Nielsen Holding in 1989 and today employs around 500 people worldwide. Nassau is also celebrating its 40th anniversary in 2010.

From 1982 until 1986, the company again increases its activities. This results in the hiring of more people and significant workshop expansions so that by this time the workshop is about 600 square meters. The company still operates as a manufacturing company with the main emphasis on subcontracting work. The customer price has now risen to DKK 125, - and the customer now pays about DKK 4.85 per kg. iron. It is also in 1986 that the company celebrates its 25th anniversary.

In 1988, the generational change begins as I join the company and we form a partnership. In 1994, I buy land and buildings at the same time as we make an expansion of 740 square meters, so that we subsequently have approx. 1500 square meters at our disposal.

In 1999 the company was transformed into a limited company and in 2002 I bought the last shares, so that today I am the main shareholder and sole owner.

In the period from 1992 to 2001 we have a certified quality management system according to the ds/iso 9000 series, but as we experience that several of our customers do not distinguish between whether they buy subcontracts from a certified subcontractor or one that is not, we choose to save the money that it costs to have a certification agency to audit us.

It is also during this period that globalization is starting to gain momentum in our industry. We now find ourselves having to compete with companies from Eastern Europe and Asia in particular. And this is not perceived as being on equal terms. Just as we also have to experience that our customers can have their products produced for half of what we have to pay for the goods. From having been involved from prototype production, zero series and actual series production and had the pleasure of sales of the products increasing, there is now a period where we may well be allowed to produce prototypes and the first series, but that many of our larger customers then move production to Eastern Europe or Asia. To our great surprise, in many cases this is even happening with Danish export subsidies!

From the beginning of 2000 until the fall of 2008, the iron and metal industry, like so many other industries, did reasonably well. But for many, it is also growth on borrowed money. So just when we thought we had survived the challenges of globalization, we had a rude awakening. During 2009, our turnover fell by about 30% and we had to lay off staff, so we went from twenty to twelve. For the first time in the twenty-two years I had been with the company, we were in the red.

Here in 2010, we should have brought income and expenditure back into balance. We have a large and flexible production apparatus that is ready to move when things start to move forward again. We are now looking forward to celebrating the company's 50th anniversary in June 2011 and hope at the same time to have the opportunity to greet customers, suppliers, former employees and some of the approximately 50 blacksmiths, machinists and technicians that we have helped to train over the years. My father, Svend Frederiksen, did not get to experience this when he passed away on April 20, 2008 at the age of 73. But I am sure he would have been both happy and proud at the thought!

Fleming Frederiksen, June 19, 2010.

[1] Jensine was one of nine daughters of master carpenter Nicolaj Pedersen from Sofienlund Sawmill in Boltinge. His one son Kresten Pedersen started Boltinge Stolefabrik and his other son Peder Pedersen later took over Sofienlund Sawmill.